|

Carburetor

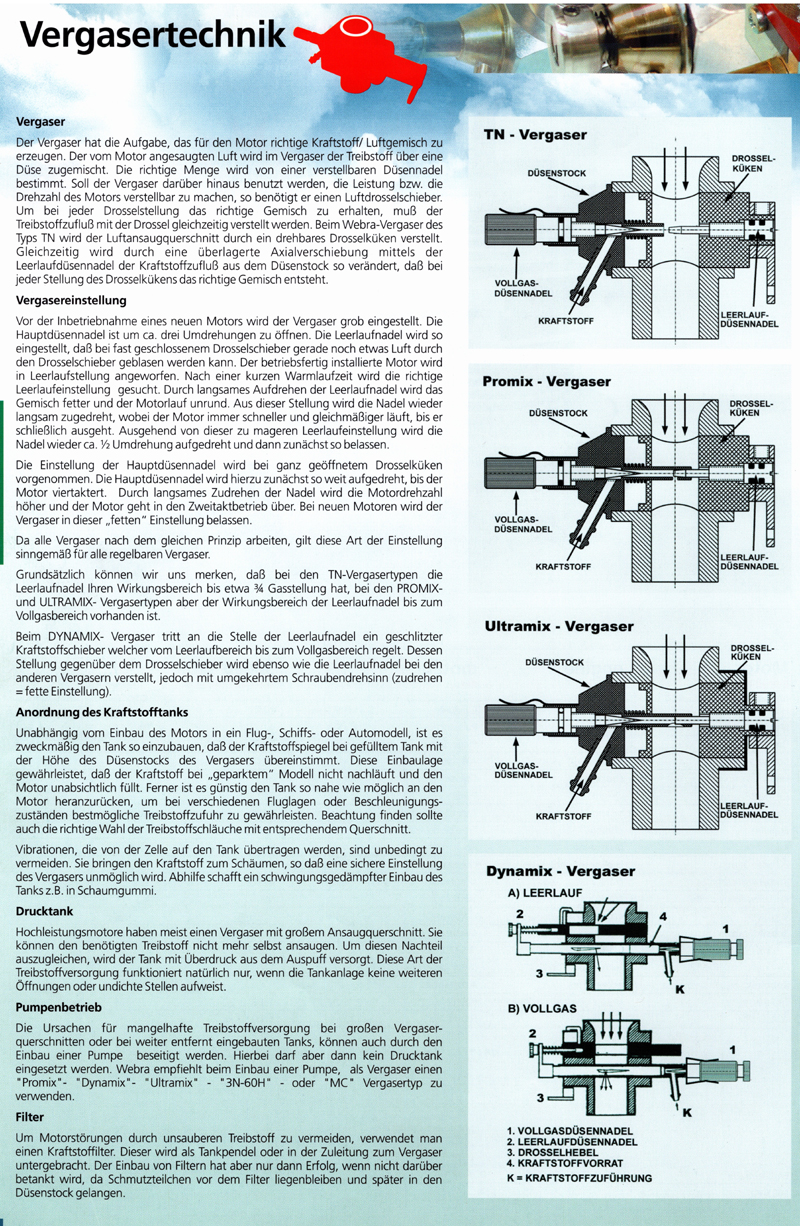

The carburetor's job is to produce the correct fuel/air mixture for the

engine. The air sucked in by the engine is mixed with fuel in the carburettor

via a nozzle. The correct amount is determined by an adjustable nozzle

needle. If the carburettor is also to be used to make the power or speed

of the engine adjustable, it needs an air throttle slide. In order to

obtain the correct mixture at every throttle position, the fuel flow must

be adjusted at the same time as the throttle. With the Webra type TN carburetor,

the air intake cross section is adjusted by a rotatable throttle valve.

At the same time, the fuel flow from the nozzle assembly is changed by

a superimposed axial displacement using the idle nozzle needle so that

the correct mixture is created in every position of the throttle valve.

Carburetor adjustment

Before starting up a new engine, the carburettor is roughly adjusted.

The main jet needle must be opened by approx. three turns. The idle needle

is adjusted so that when the throttle slide is almost closed, just a little

air can still be blown through the throttle slide. The engine, installed

ready for operation, is started in idle position.

After a short warm-up time, the correct idle setting is sought. By slowly

turning on the idle needle, the mixture becomes richer and the engine

runs irregularly. From this position, the needle is slowly closed again,

with the motor running faster and more steadily until it finally stops.

Starting from this too lean idle setting, the needle is turned up again

by approx. 1/2 turn and then left like that for the time being. The adjustment

of the main jet needle is carried out with the throttle valve fully open.

To do this, the main jet needle is first turned on until the engine runs

at four strokes. By slowly closing the needle, the engine speed increases

and the engine switches to two-stroke operation. In new engines, the carburetor

is left in this "rich" setting. Since all carburetors work according

to the same principle, this type of setting applies to all adjustable

carburetors. Basically, we can note that with the TN carburetor types,

the idle needle has its range of action up to about 3/4 throttle position,

but with the PROMIX and ULTRAMIX carburetor types the effective range

of the idle needle is available up to the full throttle range. In the

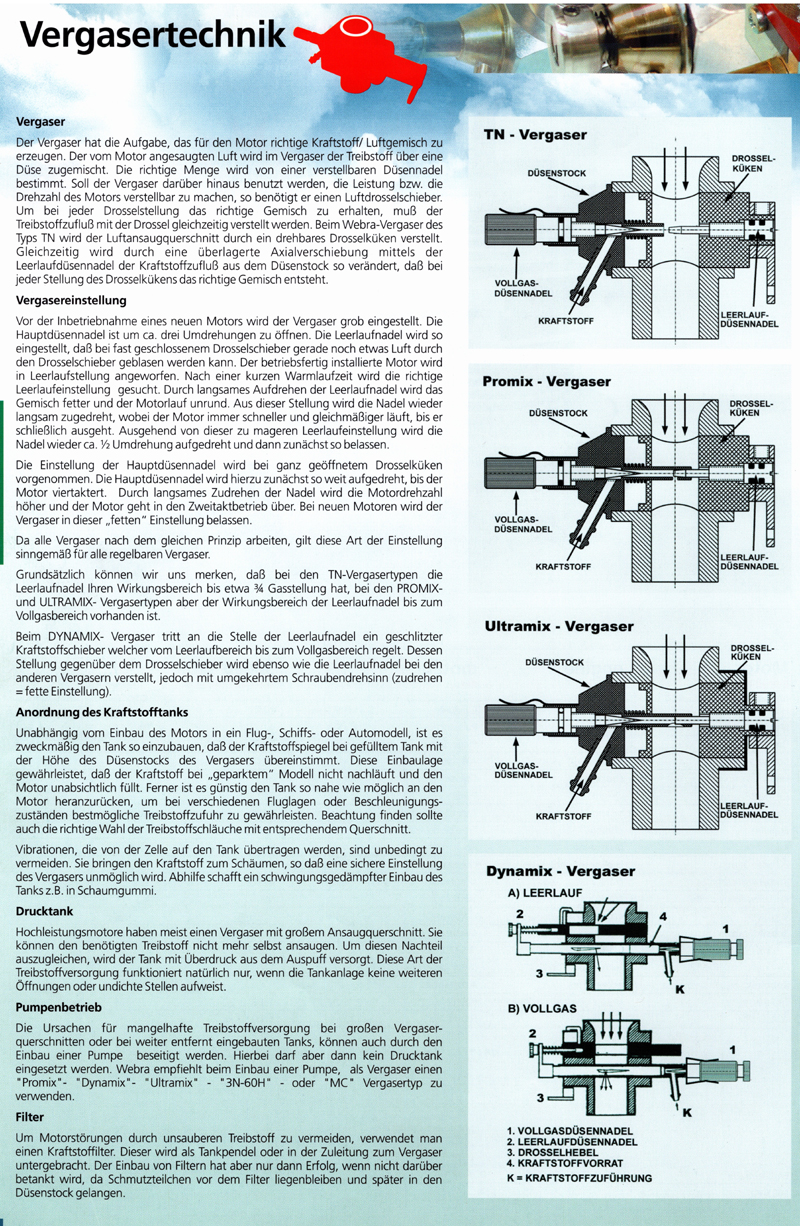

DYNAMIX carburettor, the idle needle is replaced by a slotted fuel slide

which regulates the idle range to the full throttle range. Its position

opposite the throttle slide is adjusted in the same way as the idle needle

on the other carburettors, but with the screw turning in the opposite

direction (tighten = rich setting).

Arrangement of the fuel tank

Regardless of whether the engine is installed in an aircraft, ship or

car model, it is advisable to install the tank in such a way that the

fuel level when the tank is full corresponds to the height of the carburettor's

nozzle assembly. This installation position ensures that the fuel does

not run over and unintentionally fill the engine when the model is “parked”.

Furthermore, it is advantageous to move the tank as close as possible

to the engine in order to ensure the best possible fuel supply in different

flight positions or acceleration conditions.

Pay attention

The right choice of fuel hoses with the appropriate cross-section should

also be made. Vibrations that are transmitted from the cell to the tank

must be avoided at all costs. They cause the fuel to foam, making it impossible

to safely adjust the carburettor. This can be remedied by a vibration-damped

installation of the tank, e.g. in foam rubber. Pressure tank High-performance

engines usually have a carburettor with a large intake cross-section.

They can no longer suck in the required fuel themselves. To compensate

for this disadvantage, the tank is supplied with excess pressure from

the exhaust. This type of fuel supply of course only works if the tank

system has no other openings or leaks.

Pump operation

The causes of inadequate fuel supply with large carburettor cross-sections

or with tanks installed further away can also be eliminated by installing

a pump. However, no pressure tank may be used here. When installing a

pump, Webra recommends using a "Promix" - "Dynamix"

- "Ultramix" - "3N-60H" - or "MC" carburetor

type as the carburetor.

Filter

To avoid engine problems caused by unclean fuel, use a fuel filter. This

is housed as a tank pendulum or in the supply line to the carburettor.

However, installing filters is only successful if you do not refuel through

them, as dirt particles remain in front of the filter and later get into

the nozzle assembly.

|